43 1045 steel ttt diagram

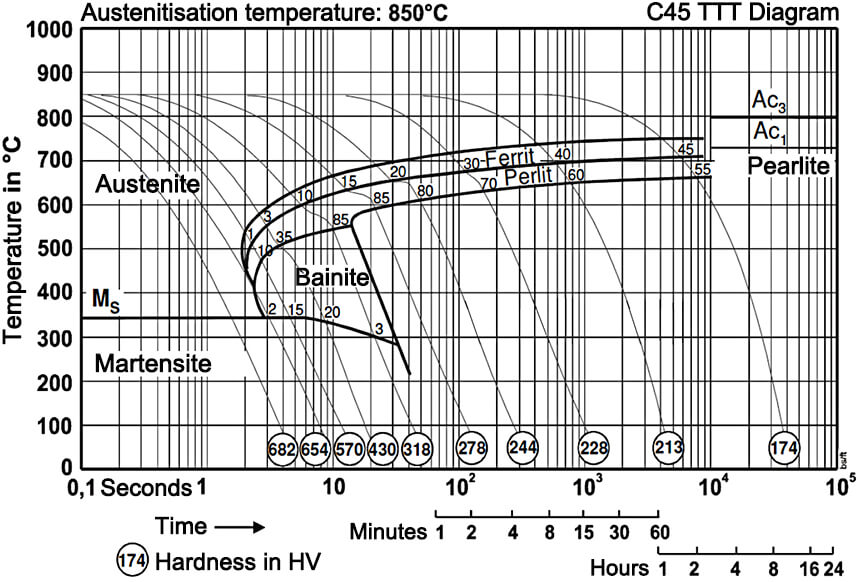

The Fe-C phase diagram depicted in Chapter 11 illustrates an important characteristic in the steel composition range which is called the 'eutectoid' which refers to the composition of a solid phase which, upon cooling, undergoes a univariant transformation into two, or more, other solid phases. 4 For a carbon steel, the eutectoid point ... Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels.This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain’s curve.The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram.

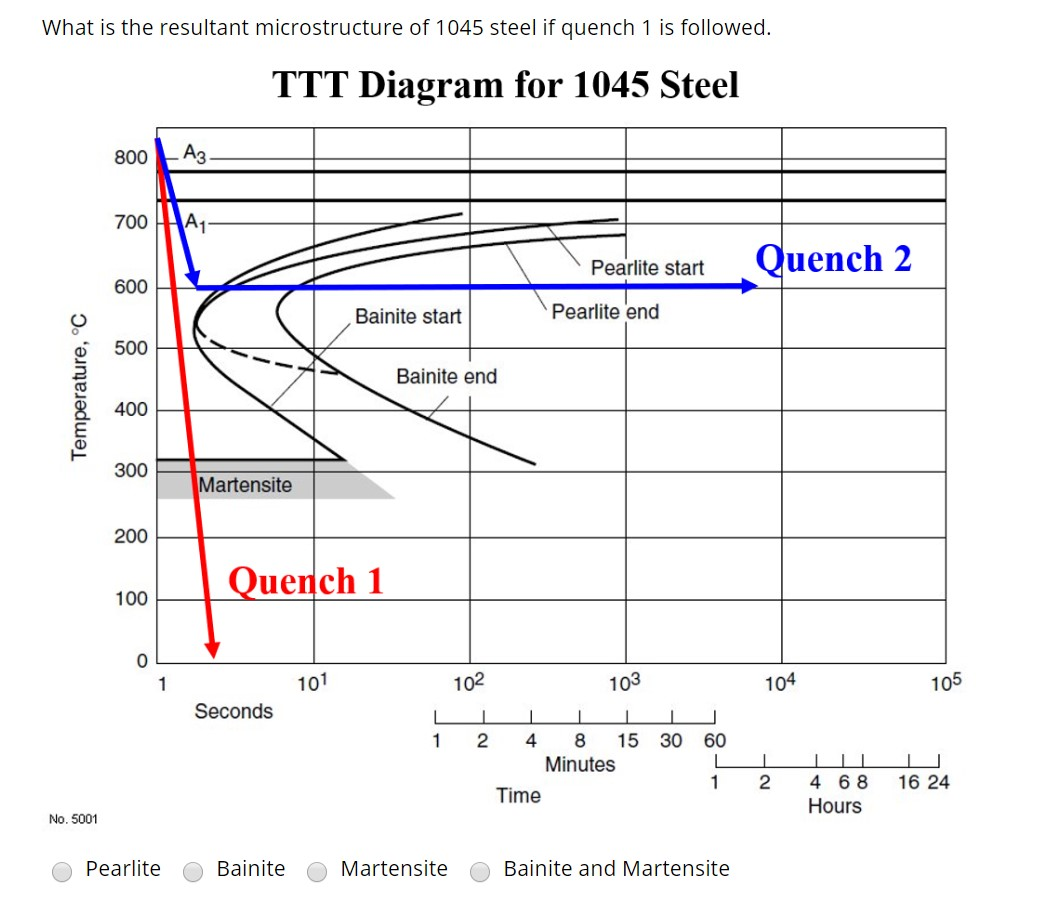

You just don't have enough alloying elements like Mo, Ni or B in carbon steel to retard the ferrite/pearlite transformation. If you quenched this material, you will form martensite. The CCT/TTT diagram for 4340 alloy steel will easily allow you to form bainite. RE: Bainitic Steel, AISI 1045. Salvatio (Materials)

1045 steel ttt diagram

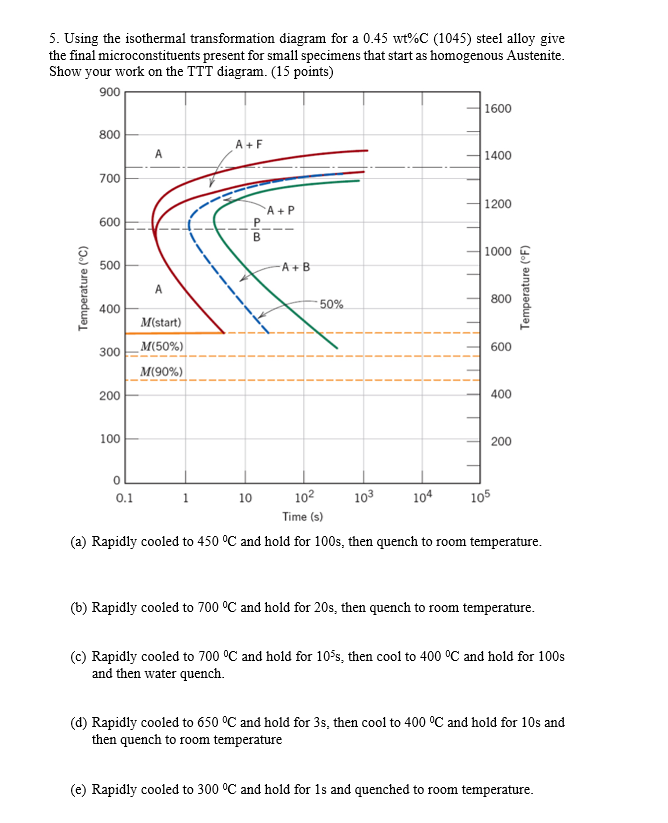

AISI 1045 steel is hypoeutectoid steel con- sisting of pearlite (P) and proeutectoid ferrite (a). ... In order to incorporate the effect of stress on the transformation, the TTT and TTA diagrams ... ASTM SAE AISI 1045 steel is one of the commonly used medium carbon steels with an average carbon content of 0.45%, medium tensile properties, good strength, toughness and wear resistance. It can be treated by annealing, flame treatment or induction hardening. C1045 is also known as 1045 cold rolled steel (cold worked), and 1045 hot rolled steel ... This led to maps of isothermal transformations using a time-temperature-transformation (TTT) diagram (3, 4) for each steel composition. These diagrams have been developed for many compositions using several approaches (5). Isothermally-transformed specimens are highly useful in teaching interpretation of microstructures.

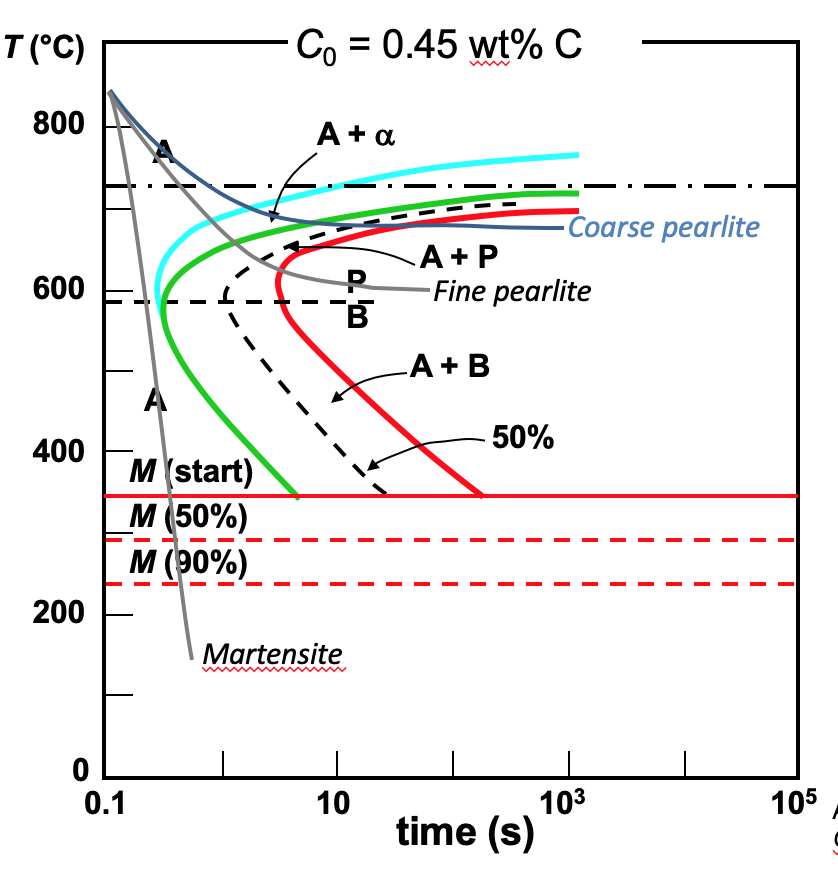

1045 steel ttt diagram. AISI 1045 Steel Steel name: AISI 1045 Diagram No.: 5001 Type of diagram: TTT Mat. No (Wr.Nr) designation: 1.1191 SS designation: SS 1672 AFNOR designation: AFNOR XC 42 TS AISI/SAE designation: AISI 1045 JIS designation: JIS S 45C Chemical composition in weight %: 0.43-0.50% C, 0.60-0.90% Mn, max. 0.04% P, max. 0.05% S Steel group: Carbon steels TTT Curves for a 1045 Ferritic Steel. Objective. The objective of this laboratory is to construct a partial Time-Temperature-Transformation (TTT) curve for a 1045 ferritic steel using light microscopy and standard stereological techniques. Background. The decomposition of austenite in hypoeutectoid steels. Figure 1 is a portion of the Fe3C ... 1045 Steel Ttt Diagram. I have made an attempt to describe TTT diagram and Heat Treatment to Experimental study of getting TTT diagram for 08% C in Steel C. Heat Treatment of schematron.org - Download as PDF File .pdf), Text File .txt) or read online. TTT diagram for eutectoid steel shown in relation to the Fe–Fe 3. TTT diagram for eutectoid steel shown in relation to the Fe–Fe 3.Dec 13, · RE: Bainitic Steel, AISI metengr (Materials) 21 Sep 04 As a follow-up, I reviewed the CCT/TTT diagram for an AISI Type carbon steel and it would appear that the ferrite/austenite upper nose protrudes before the bainite nose, meaning you would form ferrite before the bainite transformation is completed.

Determination of TTT diagram for eutectoid steel Davenport and Bain were the first to develop the TTT diagram of eutectoid steel. They determined pearlite and bainite portions whereas Cohen later modified and included M S and M F temperatures for martensite. There are number of methods used to determine TTT diagrams. These are salt bath Figs. 1-2) techniques combined with metallography and ... Phase Diagram 1045 Steel TTT Diagram 4140 Tempering Diagram Stress Relieving 4140 Phase Diagram TTT Diagram 1045 4140 Steel Ttt Diagram Wiring Diagram Pictures April 19th, 2019 - 4140 Steel Ttt Diagram Apr 08 2019 Thank You for visiting our website Today we are pleased to declare we have discovered a very Continuous Cooling Transformation Diagrams Isothermal heat treatments are not the most practical due to rapidly cooling and constant maintenance at an elevated temperature. Most heat treatments for steels involve the continuous cooling of a specimen to room temperature. TTT diagram (dashed curve) is modified for a CCT diagram (solid curve). For ... Fig. 3, TTT Diagram for 1045 Steel; Both steel specimens, A36 and 1045, can be classified as hypoeutectoid, since their carbon content is below 0.76%. Therefore, the region of interest in the phase diagram is to the far left of fig. 5. For A36, the carbon content is .25-.29 wt%, while 1045 is .45%-.50 wt%. In the case of A36 steel we used a TTT ...

For understanding, Follow TTT Diagram in Steel to learn about the critical cooling rate necessary for this transformation. ... 780 o C and 880 o C) which is then water quenched and the phase transformation of 1045 steel can be studied. Heating on different austenitizing temperature gives different mechanical properties i.e., hardness and different microstructures. Martensitic Structure is ... Time Temperature Transformation (TTT) diagram of AISI 1045 steel [9] In the present study, V-shaped arc welding of the AISI 1045 steel is modeled by using 2D Finite Element Model (FEM). The ... In which 1045 steel specimens were taken , measuring 1 inch long and ½ inch in diameter, has the chemical composition of steel in Table 1. [10] TABLE ... The purpose of these equations is to build a diagram TTT (Temperature, Time, Transformation) in the MATLAB® software 1.4 TTT diagram for 4140 steel We can gain some quantitative insight as to what happens in 4140 steel under a general thermal cooling history from a temperature in the austenite (A) regime by examining its isothermal Time-Temperature-Transformation (TTT) curve, as shown in Fig. 2. The

Examples on how to use TTT Diagrams

Ttt Diagram 1045 Steel. I have samples of AISI and in a 10*10* dimension. The CCT/ TTT diagram for alloy steel will easily allow you to form. I have made an attempt to describe TTT diagram and Heat Treatment to Experimental study of getting TTT diagram for 08% C in Steel C. The objective of this laboratory is to construct a partial Time ...

AISI-SAE 1045 - 0.45 % C ... be different than a TTT diagram. 15 Slow Cooling Time in region indicates amount of microconstituent! 16 Medium Cooling Cooling Rate, R, is Change in Temp / Time °C/s. 17 Fast Cooling This steel is very hardenable… 100% Martensite in ~ 1

Isothermal transformation diagrams for SAE 1045 steel are shown in Figure 6-4. Heat Treatment of Steels Common steels, which are really solid solutions of carbon in iron, are body-centered-cubic. However, the carbon has a low solubility in bcc iron and precipitates as iron carbide when steel is cooled from 1600 ºF (870C). The processes of ...

1045 Steel Steel name: 1045 Diagram No.: 5653 Type of diagram: TTT AISI/SAE designation: 1045 Chemical composition in weight %: 0.45% C, 0.26% Si, 0.67% Mn, 0.009% P, 0.012% S, 0.06% Ni, 0.009% Mo Steel group: Carbon steels Note: No data Reference: Not shown in this demo version. Transformation Diagram Price: 30.00 US $ Buy Online Transformation Diagram Other Steel Data links Carbides in Steel ...

Answer to Solved What is the resultant microstructure of 1045 steel if

CCT, TTT, TTS, TTP diagrams of steels. ... Steel name: AISI 1045 ... Note: Continuous cooling transformation diagram of an unalloyed steel containing 0.45% ...

transformations in steel. It illustrates how to use an equilibrium phase diagram, TTT curves, ITT curves and CCT curves to specify a heat treatme nt, understand the development of a microstructure and, to a lesser extent, the relationship between microstructure and properties. Four different heat treatments are performed.

12.1. The diagram which follows shows the TTT diagram for a coarse-grained, plain carbon steel of eutectoid composition. Samples of the steel are austenitized at 850 °C and then subjected to the quenching treatments shown on the diagram. Describe the microstructure produced by each heat treatment.

Using the isotherrnal transformation diagram for a 0.45 wt%C(1045) steel alloy give the final microconstituents present for small specimens that start as homogenous Austenite. Show your work on the TTT diagram.

Description of TTT Diagrams for Hypoeutectoid and Hypereutectod steels. Effect of alloying in TTT Diagrams.

1. Describe the heat treatment processes of 1045 (or 4140) steel introduced during the laboratory session. 2. Typical tensile stressstrain behavior for 1045 steel, in the four conditions con sidered, will be generated. From these curves for each of the four heatedtreated material states, obtain the following tensile properties:

This led to maps of isothermal transformations using a time-temperature-transformation (TTT) diagram (3, 4) for each steel composition. These diagrams have been developed for many compositions using several approaches (5). Isothermally-transformed specimens are highly useful in teaching interpretation of microstructures.

ASTM SAE AISI 1045 steel is one of the commonly used medium carbon steels with an average carbon content of 0.45%, medium tensile properties, good strength, toughness and wear resistance. It can be treated by annealing, flame treatment or induction hardening. C1045 is also known as 1045 cold rolled steel (cold worked), and 1045 hot rolled steel ...

AISI 1045 steel is hypoeutectoid steel con- sisting of pearlite (P) and proeutectoid ferrite (a). ... In order to incorporate the effect of stress on the transformation, the TTT and TTA diagrams ...

0 Response to "43 1045 steel ttt diagram"

Post a Comment